Wind

Reliability made by Schaeffler

Cost-effective wind turbines require reliable components. As one of the world’s leading manufacturers of rolling bearings and a development partner for the sector we have been producing bearing supports for wind turbines for over 30 years. We offer the right bearing solution for every wind turbine and an integrated concept for safety.

- Schaeffler Wind Power Standard

- Optimum design with state-of-the-art calculation and simulation programs

- Realistic tests on Schaeffler’s ASTRAIOS

- Innovative solutions for preventing white etching cracks (WEC)

- High equipment availability due to condition monitoring

Applications & Products

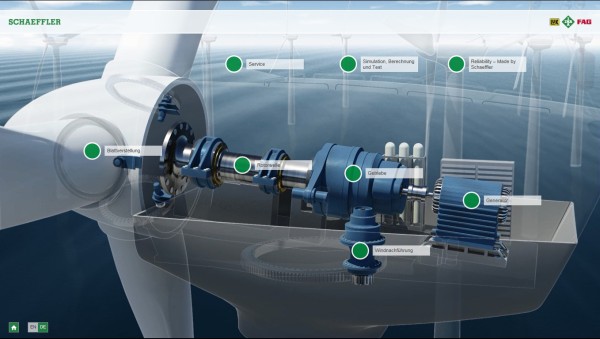

Rotor shaft

The rotor shaft bearing support is of central importance in wind turbines. This is where all the forces act that are induced by the wind. The rolling bearings are subjected to highly-dynamic loads and operating conditions. In partnership with customers, Schaeffler develops the most efficient bearing support for each case

Gearbox

Increasing megawatt ratings require larger and higher capacity gearboxes. The operating conditions for rolling bearings in wind turbine gearboxes cannot be compared with those for industrial gearboxes.

Generator

Generators in wind turbines are subject to high vibration loads. This additional permanent load has a negative influence on the cages and places strain on the lubricant.

Wind tracking and blade adjustment

Wind turbines must be aligned optimally to the wind in order to prevent extreme loads and allow cost-effective operation. Wind turbines adjust automatically due to active systems with azimuth drives and gearboxes.

Simulation, calculation and test

Our specialists work in close cooperation with wind turbine developers, manufacturers, and operators. State-of-the-art calculation and simulation programs ensure that optimum designs for bearings for wind power applications are produced. The entire system is considered, from individual rolling bearings and their components and adjacent construction through to the entire power transmission system, which is displayed and optimized using multi-body simulation programs developed in-house.